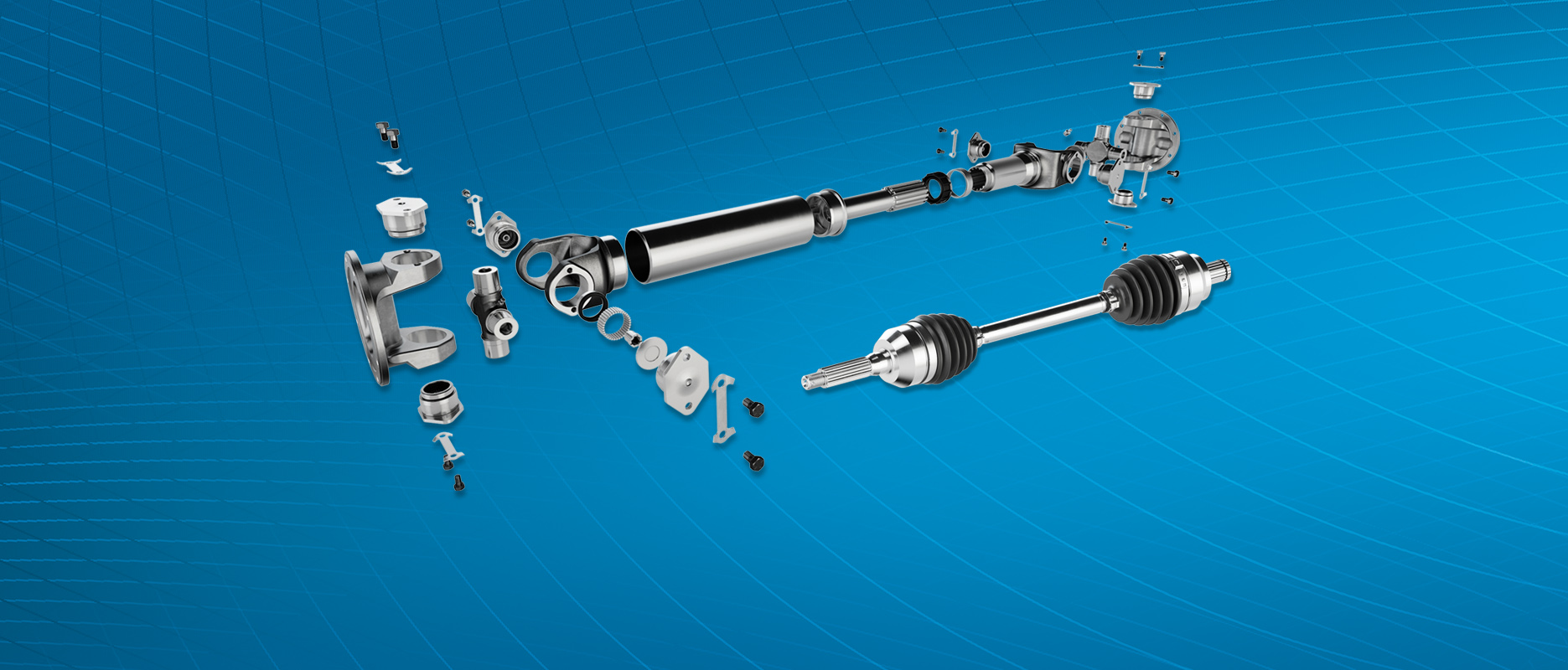

Demand Genuine Neapco

A USA based company since 1921, New England Auto Products Corporation™, Neapco, is a world-class OE supplier. Neapco’s application-specific engineering and data-controlled manufacturing processes ensure high quality and optimal performance for your vehicle.

Manufacturing Driveline Solutions® In the USA Since 1921

World-class testing and engineering provides proven performance

Data-controlled manufacturing ensures consistent quality and reliability in every piece

Industry leading product coverage and inventories

- Markets (Light Vehicle, Commercial Vehicle, Off-Highway, and UTV)

- Styles/Series (10 Series, NPL Series, Wing Bearing Series)

- Application Needs – Class Series, OE Series, Performance Series

Regional distribution – Beatrice, NE and Greer, SC

Customer focused product enhancements and innovations (ie.)

- NPL Platelock – ease of installation and elimination of cap spin

- Balanced yokes – easier/quicker to balance assemplies – time and money saver